ZTZY type screw press

===★ A machine to press the world ★===

ZTZY type screw press is a capable of continuous operation for extruding liquid organic materials, inorganic materials separation of liquid slag crushing equipment, the press machine belongs to the company and three generations of my spiral press, but it is definitely not is screw press a simple modification of the upgrade, but subversion design and change. The screen is not blocked, no requirement of feed concentration,viscosity,hardness particle size and fiber length. Press can stably and smoothly through the continuous operation, low failure rate, running and maintenance costs low, and high juice yield and the dehydration rate is the biggest characteristic, the press performance can more than the market any form of screw press, belt type press and centrifuge. Part of the fruit and vegetable juice yield reached 85%, while the core juice is also a unique function of it, part of the material after dehydration dry degree reached 20%, showing a common press or dewatering machine is difficult to reach the magical effect of, to recycle your waste re-use the extraction of juice or bring considerable economic benefits. The higher the milling efficiency and about a crop can recover the investment cost, has a very high price, so our slogan is "choose to create value".

◆For a large number of applications video, please click on the following link:

◆To determine if the material is suitable for the press machine method, please click on the order notice connection:

◆Technical characteristics:

=1, the biogas residue is a kind of complex material is not afraid to wear, smooth water, rely on is spiral and screen the effective cooperation and achieve the purpose of separating and pressing.

=2, the extrusion separator successfully resolved the screen clogging problems, its core technology is a spiral and the screen with the screen in order to achieve self-cleaning function, that is, by special device and spiral interact to stir materials, the way to avoid material holding shaft, and secondly, the material in the spiral forward in the process of the realization of material particles rub off screen blockage;

=3, the control of tail cone different in the common market of spring, hydraulic, hand wheel, and the maintenance cost is extremely low pneumatic device, through specific design, the effective realization of the control of the material crushing "back pressure", that is, set some pressing pressure, the device will automatically realizing press force control of materials, avoid slag suddenly suddenly dry wet, and the extrusion separator due to the superposition principle of compression, and is particularly suitable for assembly line work, to avoid the ordinary press needs to malpractice;

=4, press machine screen sieve are two and a half, for food processing and fruit and vegetable processing industry, you can easily open thoroughly cleaned, and can realize the network internal and external CIP alkaline cleaning without dismantling the and outer screen can achieve water cleaning time (alt.), all of these are the effective realization of the demanding requirements of the industry related to health;

=5, sandblasting, has the advantages of beautiful appearance, simple structure, drive low-speed, high torque output, low noise, no vibration, is driven both by the few parts, wearing parts need to be replaced by the less, low maintenance cost is choice for you for solid-liquid separation and the processing of fruits and vegetables.

◆Working principle:

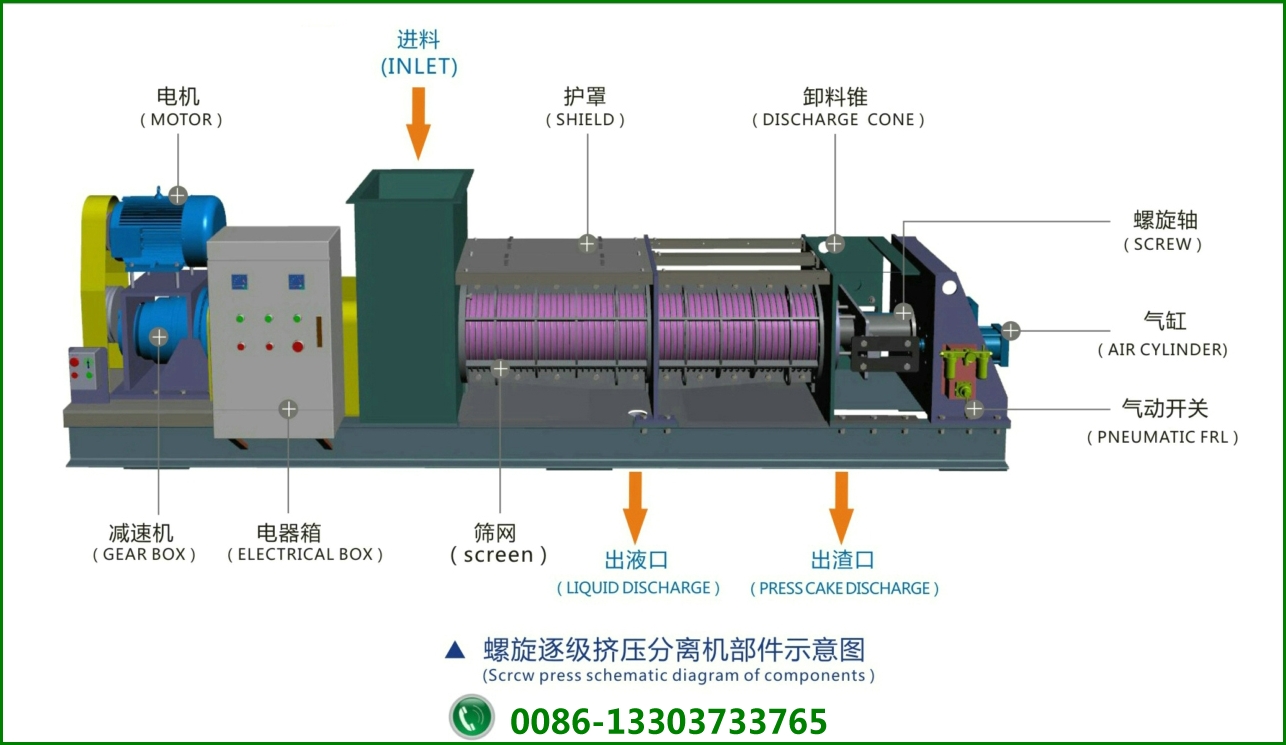

The spiral press machine based on superposition compression principle of design, mainly rely on into the material box, a screw, a screen, a gas dynamic tail cone four to achieve the material squeezing separation of purpose. Materials to be processed after pump or screw tools such as evenly conveying to the spiral extrusion separator feed mouth, through the spiral blade of extrusion and screen filter, water or juice after screen flow to under the machine water receiving disc collected through a pipe picked up press after the separation of slag through the conveyor belt to refer to the place.

◆Technical parameter:

|

Model |

Capacity(t/h) Feed rate / slag discharge |

Screw diameter (mm) |

Screw rpm (r/min) |

Motor hp (kw) |

Outline dimension Length× width× height (mm) |

Weight (t) |

|

ZTZY-120 |

0.1~0.3/0.26 |

120 |

30 |

2.2或3 |

1860×456×744 |

0.5 |

|

ZTZY-180 |

0.3~1/0.5 |

180 |

20 |

4 |

2500×550×800 |

0.8 |

|

ZTZY-250 |

0.8~3/0.93 |

250 |

16 |

5.5 |

3050×640×930 |

1.2 |

|

ZTZY-315 |

2~5/1.6 |

315 |

16 |

11 |

4000×790×1310 |

2.4 |

|

ZTZY-400 |

5~13/2 |

400 |

10 |

22 |

5000×1120×1520 |

4.5 |

|

ZTZY-500 |

8~18/3.3 |

500 |

9 |

37 |

6100×1200×1500 |

6 |

|

ZTZY-630 |

15~35/4.2 |

630 |

9 |

45 |

6700×1560×1720 |

7.5 |

|

ZTZY-800 |

25~50/7 |

800 |

7 |

75 |

7500×2300×2200 |

9 |

|

ZTZY-1000 |

30~70/8.5 |

1000 |

6 |

90 |

8100×2700×2600 |

12 |

◆Structure diagram:

◆Various types of screw press:

Note: the feeding hopper and the supporting legs on the feed box belong to the custom component.

◆More screw press HD picture please click on the picture center:

- Copyright:Xinxiang City Zhongtian Xinghuo Machinery Co.,Ltd Address:Beihuan Road,Xinxiang City,China E-mail:ztcorp@126.com

- Tel:+86-373-3332133 Fax:+86-373-3332133 QQ:1604288169 aliwangwang:xxsztjxie Perennial legal counsel:Fan Yongzhi